A professional aircon technician needs a diverse range of tools and equipment for efficient and safe repairs. Essential tools include a multimeter, refrigerant gauges, vacuum pump, leak detector, cordless drill, and various screwdrivers and wrenches. Additionally, specialized tools like a coil fin straightener, core removal tool, and thermal imaging tools can be helpful for diagnosing and repairing specific issues.

Here’s a more detailed look at the equipment:

Core Tools:

Multimeter:

Essential for measuring electrical voltage, amperage, and resistance to diagnose electrical problems.

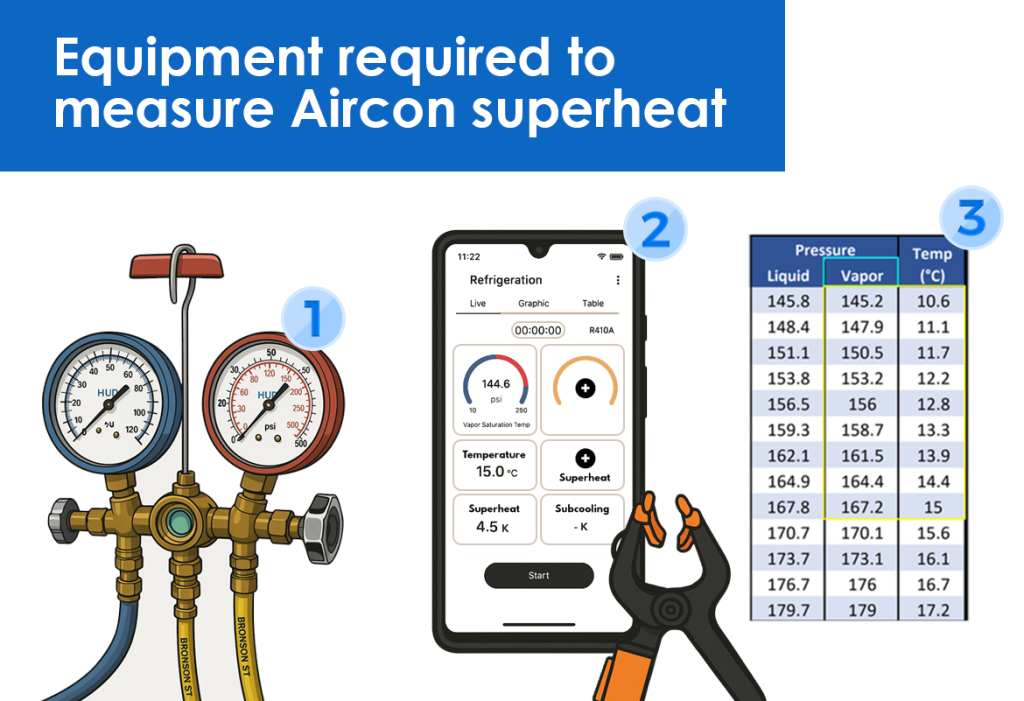

Refrigerant Gauges (Manifold Gauge Set):

Used to measure refrigerant pressure and temperature, crucial for diagnosing and servicing refrigerant systems.

Vacuum Pump:

Used to evacuate air and moisture from refrigerant lines, a crucial step in servicing and repair.

Leak Detector:

Identifies refrigerant leaks in the system, helping to pinpoint the source of the problem.

Cordless Drill:

Provides power and versatility for drilling holes and tightening screws in various locations.

Screwdrivers and Wrenches:

Used for opening and closing panels, securing components, and working with various fasteners.

Specialized Tools:

Coil Fin Straightener:

Used to straighten bent fins on the condenser and evaporator coils, improving airflow and efficiency.

Core Removal Tool:

Extracts valve cores from refrigeration units, facilitating access to the refrigerant system.

Thermal Imaging Camera:

Detects temperature variations in the system, allowing for easier identification of leaks, blockages, and other issues.

HVAC Data Logger:

Collects data over time to monitor the performance of the HVAC system and identify potential problems.

Pipe Wrench:

Used for connecting and disconnecting pipes, especially for copper tubing.

Tube Cutter/Bender:

For cutting and shaping refrigerant lines, ensuring proper fit and connections.

Welding Equipment:

May be necessary for repairing refrigerant lines or other components.

Safety Gear:

Gloves, safety glasses, and respirators are essential for protecting the technician from hazards.

Additional Tools:

- Measuring Tape: For accurate measurements during installation and repair.

- Vacuum Cleaner: For removing dust and debris from the HVAC system.

- Step Ladder: For accessing higher-up components.

- Flashlight/Headlamp: For working in dark or poorly lit spaces.

- Inspection Mirror: For accessing hard-to-reach areas.

- Utility Knife: For cutting insulation and other materials.

- Tin Snips: For cutting sheet metal.

By having these tools readily available, a professional aircon technician can confidently diagnose and repair a wide range of air conditioning issues.

Leave a Reply